Simplify your alarm management

Alarm Manager provides a comprehensive solution for organisations facing challenges in alarm handling and compliance with industry standards.

Mipac's software is trusted by Operations Managers and Metallurgists at:

Poor alarm systems hinder operations

Inadequate situational awareness

Operational teams encounter alarm flood events, disabled alarms and stale alarms, leading to information overload and reduced situational awareness. Operators are also alerted to irrelevant alarms such different plant areas or maintenance-related issues.

Compliance and safety risks

Inadequate alarm management practices can increase the risk of equipment failures and compromise operational safety. Failure to address alarms promptly and effectively may lead to equipment malfunctions, unplanned downtime, and potential harm to personnel.

Inconsistent alarm reporting

Without a dedicated Alarm Management application, organisations struggle to consistently report alarms according to the ISA 18.2 recommendations. This leads to variations in alarm handling practices across different systems and business units.

Improve operational safety, reduce downtime & enhance plant performance with Alarm Manager

Enhanced operational safety

The Alarm Manager application helps organisations prioritise and respond to alarms effectively, reducing the risk of critical safety or environmental incidents. By adhering to industry standards and best practices, it ensures that alarms are properly managed and operators can take appropriate actions in a timely and controlled manner.

Improved compliance

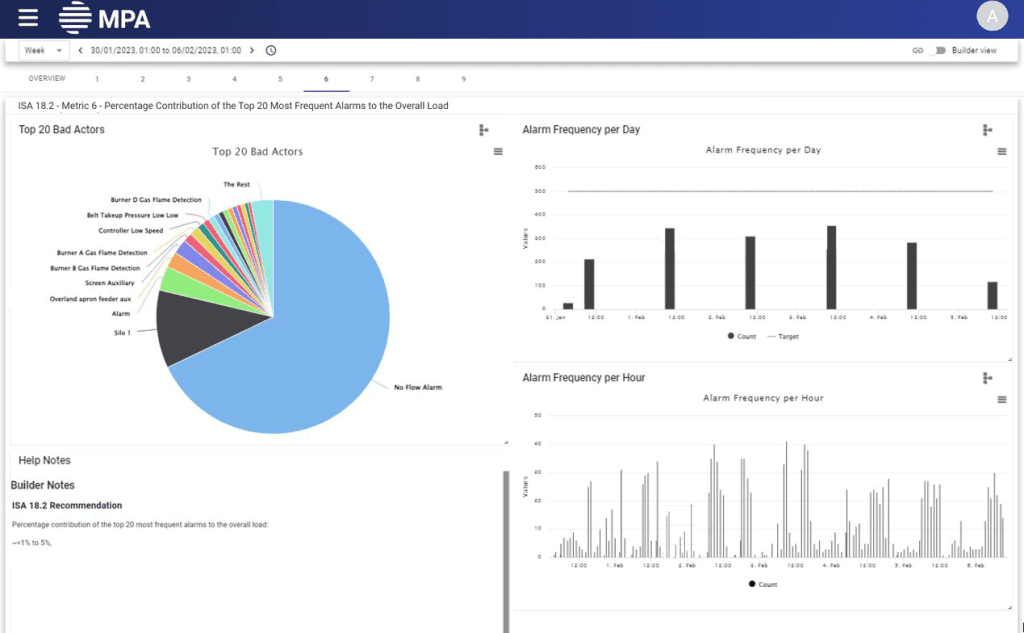

The Alarm Manager application aligns with the ISA 18.2 standard, providing organisations with a framework to meet regulatory requirements and industry guidelines for alarm management. It helps organisations establish consistent alarm handling practices and reporting mechanisms, facilitating compliance audits and demonstrating adherence to industry standards. The application ensures sustained compliance through continuous monitoring and reporting, preventing alarm systems from drifting back to a non-compliant state.

Streamlined alarm rationalisation

The application offers a centralised repository for alarm information. The master alarm information allows teams to collaborate on the prioritisation of alarm rationalisation to reduce alarm floods, stale and disabled alarms. Operational and situational awareness is improved as teams rationalise alarms. In addition, with the application’s alarm lifecycle management capabilities, organisations can address alarm-related issues proactively.

Bring all of your plant's data together in one place with the MPA software suite

Alarm Manager combines seamlessly with all of our MPA suite applications. It’s a powerful collection of tools designed to make it easier to run your process plant.

Not only can you visualise plant processes live, but with the MPA suite you can coordinate responses to deviations, manage logsheets and alarms more easily, and automate production reporting.

Combined, these tools give you access to powerful analytics that will help you discover hidden problems so you can optimise your plant and hit your targets.

How it works

Setup

We’ll connect Alarm Manager to your historical alarm database and provide prebuilt ISA 18.2 reports for seamless integration.

Rationalise

Use our prebuilt reports to prioritise efforts on improving your alarm system.

Maintain

Continuously track alarm system performance against benchmarks to ensure sustained reliability.

Reduce alarm noise and downtime with

Alarm Manager

FAQs

Alarm Manager leverages your existing control system alarm information, meaning the data is kept at its source. We will establish a new master alarm database which can be stored locally on the MPA server or in an existing SQL Server.

Alarm Manager, part of the MPA suite of applications, offers a comprehensive solution for effective alarm management in industrial processes. It includes the following key features and functionalities:

Alarm Reporting and Tracking: Alarm Manager allows organisations to report alarms according to the ISA 18.2 recommendations, ensuring standardisation and consistency in alarm handling practices.

Master Alarm Database Management: The application introduces a central repository for all alarm-related information, enabling organisations to efficiently track and manage alarms throughout their lifecycle.

Alarm Analytics and Reporting: Alarm Manager provides advanced alarm analysis and reporting capabilities, empowering organisations to identify patterns, trends, and recurring issues for continuous improvement.

Integration with Existing Control Systems: Alarm Manager seamlessly integrates with various control systems commonly used in industrial processes, ensuring compatibility and smooth implementation without major disruptions.

We understand that different customers have different support needs, which is why we offer two levels of support. Our standard support package is designed for customers who need basic support, while our premium support package is ideal for customers with more complex needs or customised solutions.

Standard support provides access to our knowledgeable support team for assistance with any software-related issues you may encounter. Standard support covers typical software application issues such as bugs and incidents. Standard support will be available during normal Brisbane business hours.

Premium support offers access to expertise for complex issues that may require specialised knowledge supporting application or infrastructure problems. Premium support can be tailored to the size and complexity of the installed system and the desired response timeframes. Premium support also provides access to application specialists for minor additions or improvements.

Our solutions can be implemented in as little as two weeks.

The implementation timeframe of our solutions can vary depending on several factors such as whether there is existing infrastructure in place and if you require any site-specific reports.

If an out-the-box Alarm Management application is required, such as connecting to an existing historical alarm database, and setup of a Master Alarm Database, the implementation can take anywhere from 2-4 weeks once the base system is set up. Our solutions can be implemented within this time frame, but it’s important to note that the exact duration will depend on the specific requirements of each project.

Read more about Mipac's software

Short Interval Control (SIC) has emerged as a powerful method to drive continuous improvement in mining operations. By enabling real-time decision-making and …

The latest MPA update delivers performance enhancements, workflow improvements, and new features designed to streamline the builder experience and support client projects. …

For most metallurgists and plant operations managers, Excel is something you need to use daily to do your job. It’s incredibly powerful …