Increase production through operational insight and foresight

Loop Performance is purpose-built to navigate the complexities and challenges of managing control loops in complex processing operations. This application is dedicated to enhancing plant stability, operational safety, and efficiency, making it an essential tool in modern process control environments.

Mipac's software is trusted by Operations Managers and Metallurgists at:

Inonsistent control loop performance can lead to significant issues

Poor performance

Typical operations contain hundreds of control loops and lack the ability to continuously and effectively monitor their health and performance. This leads to delayed responses to performance deviations. Furthermore, teams struggle to prioritise tuning of non-performing loops that are critical for production, quality or safety.

Operation instability

Without detailed insights into each loop's performance, optimising them becomes a hit-or-miss process, often leading to instability and sub-optimal plant operations.

Downtime and safety risks

The lack of adequate loop performance monitoring tools prevents early detection of issues, meaning routine maintenance, calibration or loop tuning is often missed. Failure to address control loops promptly and effectively may lead to equipment malfunctions, unplanned downtime, and potential harm to personnel.

Addressing these challenges is crucial to enhance operational safety, reduce downtime, and optimise plant performance

Stay ahead of potential problems with Loop Peformance

Reduce plant variability

The Loop Performance application is instrumental in decreasing process variability, a key factor in maintaining consistent product quality and operational stability. By optimising control loop performance, teams ensure that operational parameters remain within desired limits, leading to more predictable and stable plant operations. This stability is crucial for meeting production targets and maintaining high-quality standards.

Bring all of your plant's data together in one place with the MPA software suite

Loop Performance works seamlessly with the entire MPA suite, providing a comprehensive set of tools to simplify process plant operations.

The MPA suite enables real-time visualisation of plant processes, streamlined management of logsheets and alarms, coordinated responses to deviations, and automated production reporting.

These tools come together to deliver powerful analytics, helping you identify hidden inefficiencies, optimise operations, and stay on track to meet your targets.

How it works

Setup

We’ll integrate the Loop Performance application with your critical control loops for a tailored setup.

Visualise

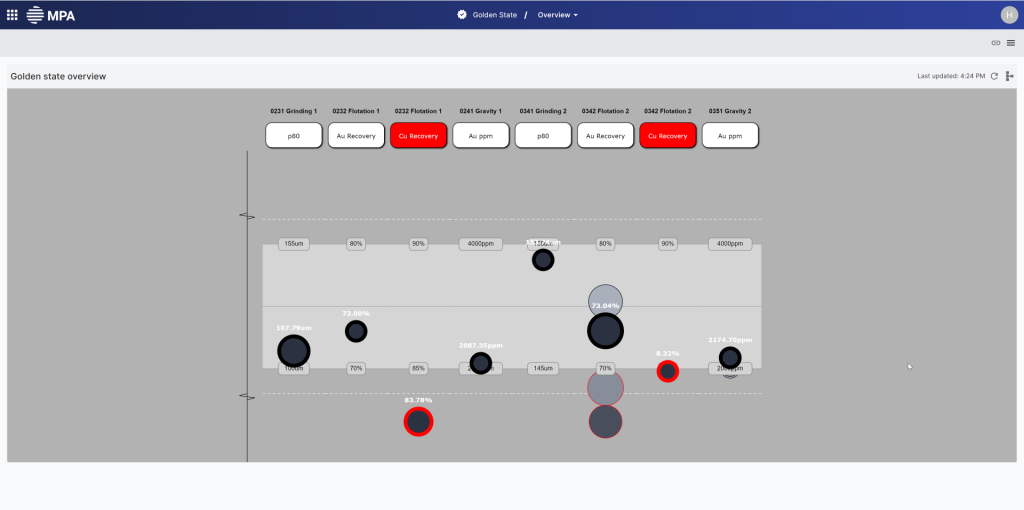

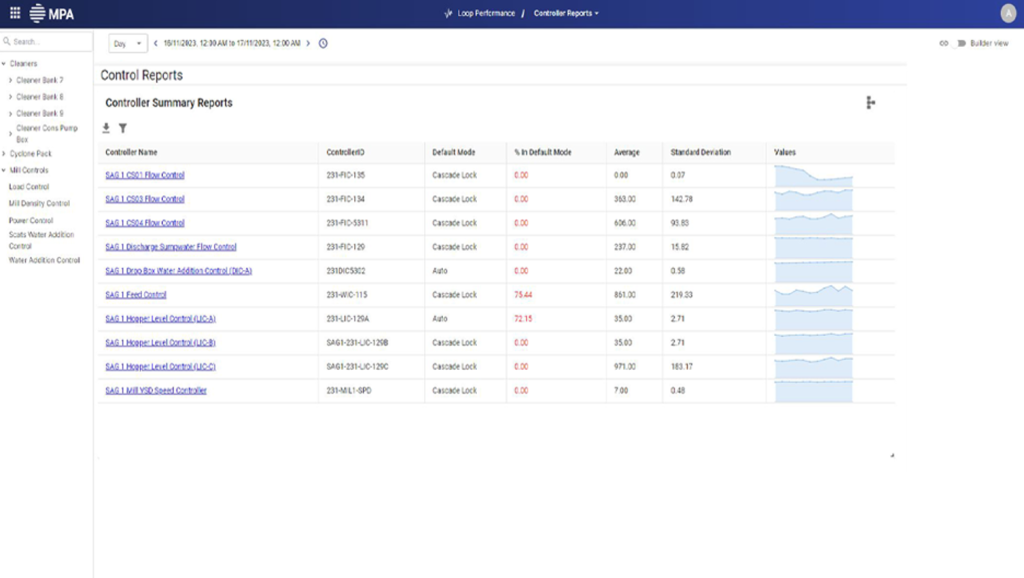

Monitor control loop performance in real time to identify and address poor performance.

Optimise

Tune underperforming loops to minimise process deviations and enhance stability.

Discover how Loop Performance can help your complex processing operation

FAQs

The Loop Performance application integrates with your control system through AVEVA PI AF, ensuring investments in existing infrastructure are leveraged. We will establish a new master control loop database (where required) which can be stored locally to the MPA server or in an existing SQL Server.

The Loop Performance application, part of the MPA suite of applications, offers a comprehensive solution for effective control loop management in industrial processes. In addition to the features listed above, the application allows unlimited users, tags, control loops, and areas within an asset.

We understand that different customers have different support needs, which is why we offer two levels of support. Our standard support package is designed for customers who need basic support, while our premium support package is ideal for customers with more complex needs or customised solutions.

Standard support provides access to our knowledgeable support team for assistance with any software-related issues you may encounter. Standard support covers typical software application issues such as bugs and incidents. Standard support will be available during normal Brisbane business hours.

Premium support offers access to expertise for complex issues that may require specialised knowledge supporting application or infrastructure problems. Premium support can be tailored to the size and complexity of the installed system and the desired response timeframes. Premium support also provides access to application specialists for minor additions or improvements.

Our solutions can be implemented in as little as two weeks.

The implementation timeframe of our solutions can vary depending on several factors such as whether there is existing infrastructure in place and if you require any site-specific reports. If an out-the-box Loop Performance application is required, connecting to a few critical loops the implementation can take anywhere from two to four weeks once the base system is set up. Our solutions can be implemented within this time frame, but it’s important to note that the exact duration will depend on the specific requirements of each project.

Mipac has a capability transfer philosophy. MPA utilises templates making it simple to extend and evolve your system as changes or new requirements are introduced.

If you don’t already have an MPA Server installed, we would require a virtual or physical server, ideally with Windows Server 2019. We would require administrator access to the server to install the pre-requisite software and configure MPA for connection to your plant data.

You will require an AVEVA PI historian with a PI AF (Asset Framework) server. If you don’t have AF setup yet, Mipac can assist with this too. In order for MPA to connect to AVEVA PI, you require the PSA (PI System Access) licence. Mipac can support you with obtaining the licence, or you can liaise directly with your AVEVA account manager.

Working with your IT group, Mipac would also require a service account to access the PI Data Archive and PI AF Server.

Read more about Mipac's software

You can’t manage what you can’t see, and in mineral processing plants, that means keeping a close eye on your process data. …

Most metallurgists are wizards in Excel. And rightly so, it can be a powerful tool to keep mineral process plants running smoothly. …

Chances are, your process plant relies heavily on manual processes and outdated systems. While there is a wide range of software tools …