Why instrumentation engineering?

Do you trust the equipment and instrumentation on your site?

How do you know you’ve installed the right models correctly, that they’re calibrated and producing accurate data that will help you make the right decisions?

If any of these questions have ever crossed your mind, you’re not alone.

Instrumentation issues are extremely common on mine sites, and as process or operations personnel, you’re often not only dealing with harsh environments in remote locations, but also the demands of your 24/7 operations.

But the impact of instrumentation issues is significant. Instruments that produce inaccurate data can lead to safety hazards, production slowdowns and difficulty meeting environmental regulations.

In short: correctly installed, functional and accurate instrumentation is critical for the success of your operation.

Common instrumentation challenges

Instrumentation challenges can impact the safety, productivity and profitability of your mining operation and affect you whether you’re a senior leader, operator, technician or maintenance worker.

For senior process & operations managers

If you’re a senior process or operations manager, common instrumentation challenges you may be facing include:

- Not knowing if your equipment is trustworthy

- Juggling the 24/7 demands of your operations

- Managing budgets related to instrumentation upgrades

- Ensuring staff – including engineers, operators, technicians and maintenance personnel – are adequately trained on the use of equipment

For operators & technicians

If you’re an operator or technician, common instrumentation challenges you may be facing include:

- Not being sure whether your site has the correct instrumentation and equipment models (or why the ones you have were chosen, installed and set up)

- Not knowing whether your instrumentation is calibrated and producing accurate, meaningful data

- Unstable instrumentation that is affected by dust, vibration and/or extreme temperatures

For maintenance personnel

If you’re in maintenance, common instrumentation challenges you may be facing include:

- Time constraints in taking instruments offline for maintenance, due to the 24/7 nature of your operation

- Outdated or unreliable equipment

How addressing instrumentation challenges will benefit your site

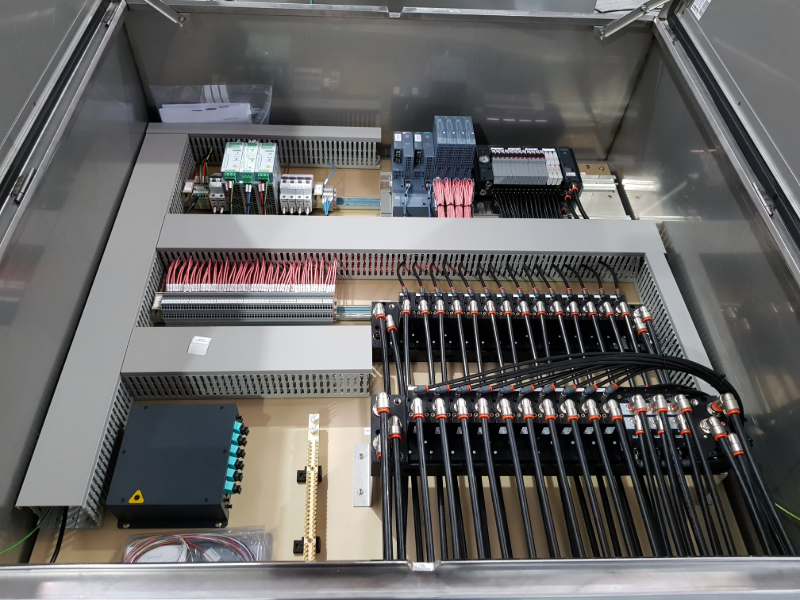

Good instrumentation engineering is the critical link between field measuring equipment and operations control systems. Addressing your site’s instrumentation challenges will enable you to:

- Ensure that your instrumentation and control system design provide accurate and adequate information about the process parameters of the system being controlled or monitored to ensure safe, reliable, continuous and economical operation of your plant

- Avoid guesswork or imagination of operators during plant operation

- Improve the operational efficiency of your plant and reduce the potential for costly errors

- Reduce the required manpower for operations and increase product output through good automation and instrument and control valve choice

- Enable faster reaction times in addressing faults and alarms

How we can help

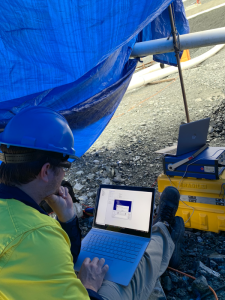

At Mipac, we’ve been helping clients in the mining sector with instrumentation issues for decades.

Our expert team is experienced in scoping existing brownfield sites for upgrades. This includes:

1. Plant instrument and control valve audits

Conducting plant instrument and control valve audits based on your specific requirements. These audits evaluate your installed equipment’s suitability, condition and reliability that could adversely affect the control and plant performance

2. 'As built' inspections

Conducting plant “as built” inspections based on existing plant equipment physical design (this includes redline marking up any changes from the original design on existing P&IDs)

3. Upgrading equipment

Upgrading obsolete and unreliable equipment using the latest vendor supplied technology solutions (including procurement, installation and commissioning supervision assistance)

4. Optimising your process control system design

Upgrading/optimising your process control system design to improve throughput, long term efficient control, safe operation and plant reliability

Our instrumentation engineering specialists can also assist with new project design and greenfield projects. This includes:

5. Generating preferred instrument and control valve lists

Generating preferred instrument and control valve lists based on your plant design requirements

6. Developing technical specifications

Developing technical specifications and documentation using approved software

7. Sourcing and procuring

Sourcing and procuring the correct instrumentation and control valves, including control and monitoring systems

8. Collaborating with your team

Working with contractors, control systems engineers and process engineers to provide a robust operating system

9. Commissioning

Providing commissioning assistance

Our approach

Great instrumentation engineering design is based on the latest technology and an excellent understanding of your deliverables, budget and preferred equipment requirements, plant area classification, process materials to be measured as well as safety and control system requirements.

Our approach to instrumentation engineering is to make use of the process flow drawings and P&IDs you supply to us to build instrument and control valve lists. We then utilise specific software systems, together with the instrument and control valve list, to create datasheets, schematics, I/O lists and loop drawings. These form the core on which instrument selection is finalised and a detailed control system program is designed.

Why work with us?

If you’ve got an instrumentation-related problem, chances are, we’ve seen it before. Our expert instrumentation engineers bring decades of experience from large and small sites across the world including hazardous area knowledge – from dust to petrochemicals.

As a company, we have over 600 greenfield and brownfield projects under our belt, and we pride ourselves in our reputation of going beyond the solution, working with our clients to co-design solutions that fit their specific needs. In short: we don’t take a cookie-cutter approach.

Instead, we bring together multidisciplinary engineering teams and work closely with both control systems and process engineers to fully understand your specific challenge.

We love learning and sharing our knowledge and are constantly adapting our methodologies and processes to align with the latest technologies and innovations offered in the market.

That being said, we prefer to mix tried and tested measures with innovative technologies, treating each instrumentation engineering challenge on a case-by-case basis.

Instrumentation engineering case studies

Interested in learning more?

Contact us to learn more about how your site might benefit from our instrumentation engineering services.

Read more on instrumentation engineering

When she was 10, she was already tutoring younger kids in maths – in between trying to sell coconuts on her local beach in Itaituba, Brazil. She’s interned in a bank, taught at a university, and came to Australia on holiday with just one bag, never intending to stay. We sat down with Mipac Control Systems Engineer Nagila Ribeiro to talk about her career journey to date, including why she chose to study engineering, how she’s dealt with gender discrimination along the way and why she turned down a job offer with a major Australian mining company to join the Mipac team earlier this year.

4 minute read It’s been six months since Process Engineer Andrew Yang made the move from Townsville to Brisbane to join Mipac’s …

Given that most operations don’t always have in-house expertise, you may need to outsource to a Main Automation Contractor (MAC). Outsourcing this responsibility will allow you to tap into trusted experts who specialise in the field who can guide you through the whole process and offer ongoing support.